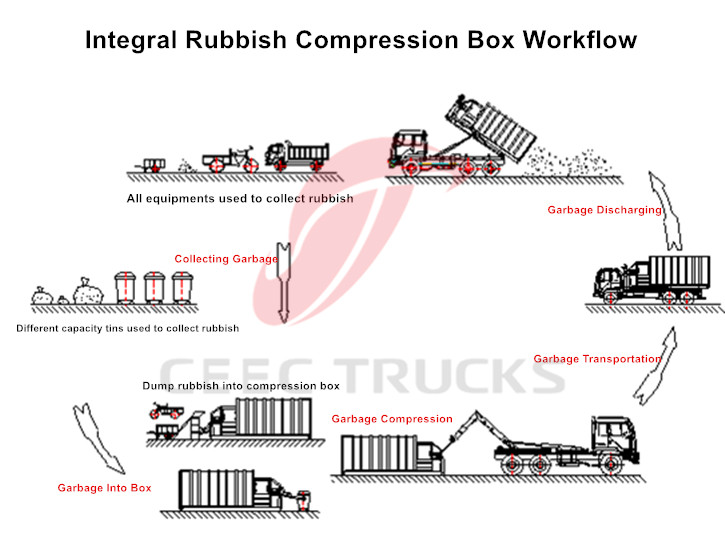

This series Integral Rubbish Compress Box is our new generation equipment whose technology is introduced fromGermany. It consists of rubbish storage box, compress structure, skip structure,electrical and hydraulic control system, etc. It has theadvantages of compact structure, flexible layout, convenient operation, nobooth and foundation requirement, it is used at street, hospital, school, park,square and so on. It is the ideal rubbish process equipment of city sanitation department and other government department.

Advanced Features:

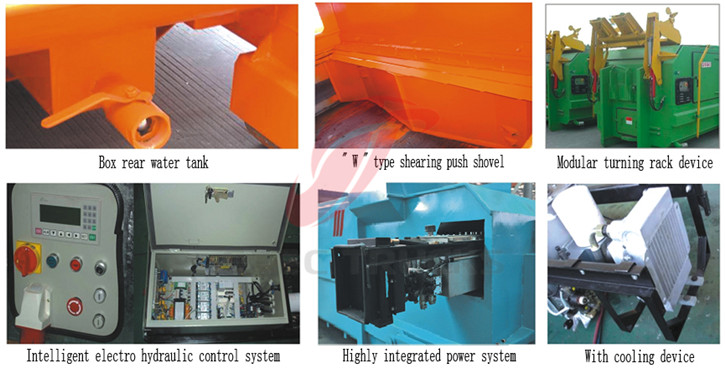

Modularization design,independent run, doesn’t require other booth or equipment, flexible layout.

1. Compressor power is 7.5kw, large feeding capacity, high working efficiencyand anti-impact performance.

2. It has the double sealing design of back door ‘B type’ sealing and bottomwater storage, the complete box sealing design in order to avoid second pollution during transportation.

3. It adopts 15Mn steel plate (thickness more than 5mm), sliding wearingparts adopts high tension nylon, reasonable structure and long workinglifetime.

4. It adopts taper design (front small and back big), easy for discharge therubbish, moreover, there is also rubbish cutting and rubbish anti-rebound device.

5. It adopts PLC control system to achieve man-machine informationcommunication, system mode real time display, simple and high efficiencyc ontrol system.

6. All electrical and hydraulic elements adopts international famous brand,just like ABB, ATOS, it has more safety and reliability.

7. All structures of the equipment adopts shot blasting, rust cleaning andpainting process. The painting oil is from Nobel or COSCO Kansai paint and haslong working life.

Mobile Garbage Compression Stations Feature:

● Garbage box body is made of high strength weathering steel plate by overall welding and with beautiful appearance, light weight, high structural strength, corrosion resistance.

● Enclosure door sealing device can be adjusted to avoid the secondary pollution in the process of transportation.

● Using screw manual open and close the back door and in the driving room can finish the back door opening and closing operation and garbage discharge.

● Force-air cooling device of hydraulic system for temperature control is optional. In high temperature season can undertake heavy load and continuous garbage loading and compression in the outdoors.

● Feeding mechanism with automatic buffer device can strike of hopper and garbage with ground in the process of hopper working.

● Cover a small floor area, convenient and flexible for transitions without civil engineering.

● A truck with various tanks to cycle transportation with high working efficiency.

● Compression head adopts double curved shape design can effectively improve the crushing and compression efficiency of garbage; Garbage tank lifting device not only can lift standard garbage tanks but also larger volume receiving hopper according to the users’ needs.

● Safety device, safety features include:

A.Installing the side feeding door safety device to the ensure safety when all system stops working in the open state of side feeding door.

B.Equipped with the power key lock and all cases of emergency stop button to improve safety performance.

| Items |

Parameters |

||

| Type A |

Type B |

||

| Garbage tank volume |

m3 |

13 |

18 |

| Compression tank volume |

2.4 |

3 |

|

| Compression type |

|

Horizontal Compression |

|

| Max. Working pressure |

Mpa |

20 |

|

| Compression stress |

T |

280 |

320 |

| Motor power |

Kw |

5.5/5.7 |

|

| Loading type |

|

Directly loading; Tilting tank; Tipping bucket |

|

| Tipping bucket volume |

m3 |

2~3 |

2~4 |

| Tilting tank volume |

m3 |

240/660 |

240/660 |

| Outer dimension (L*W*H) |

mm |

4800x2470x2400 |

6130x2470x2400 |

| Distance of hook and mudsill |

mm |

1572 |

1572 |

| Mudsill dimension |

mm |

1064 |

1064 |

| Total weight |

Ton |

4.1 |

4.7 |

| Voltage |

V |

380V/50Hz |

|

| Control mode |

|

PLC Intelligent Control system |

|

| Rear door locking type |

|

Hydraulic cylinder lock or manual wrench |

|

Skype

Skype